Bottom painting 101

I started painting boat bottoms with antifouling paint in 1972. As a diver engaged in boat bottom cleaning, I was faced with a problem; the paint jobs that came from the Boat Yards in Marina Del Rey were difficult to maintain; They didn’t use the best quality of paint, apply enough coats and/or use the right type of paint in the high wear areas. The high wear areas are those places of the boat bottom that are exposed to the most sunlight and are consequently scrubbed more by a diver hired to clean boat bottoms. Due to the amount of scrubbing required, the diver can go through the paint if (1) There are not enough coats, (2) the paint is not a hard oil base paint, and (3) The toxicity or quality is not up to retarding marine growth. Generally The High wear areas on powerboats are the bow, waterline, rudder and stern, and bow, waterline and rudder on sailboats.

To solve the problem I discussed above, 2 extra coats of antifouling paint were applied over the first 2 original coats in the high wear areas, making a minimum of 4 coats where needed most. The antifouling paint I used was a hard oil base paint containing a high cuprous oxide (copper) content because of it’s ability to retard marine growth.

Bottom Painting 102

Around 1978 I got the idea to coat all of the underwater bare metal fittings and running gear on power and sailboats with 2 coats of an epoxy barrier coating followed with 2-4 coats of antifouling paint. At this time I had 4-5 years of experience with coating iron keels on sailboats with this epoxy and thought why wouldn’t it work on the underwater metal fittings and running gear as well? The bare metal fittings and running gear consists of Propellers, struts, rudders, trim tabs, engine water intake screens, and so on.

In the past, other divers and myself had to scrape all the bare underwater metal fittings of coral 1-2 times a month in the Winter and 2-3 times a month in the Summer. Without an epoxy barrier coating between the metal and the antifouling paint there would be a reaction. the antifouling paint would either peel off of the metal or become inactive; Most effective antifouling paints contain copper (cuprous Oxide) which can conduct electricity and always has a bad reaction when applied directly over metal. If the metal running gear and fittings below the waterline were not coated with epoxy and painted with antifouling paint, the diver would spend more time cleaning the bare metal, than the antifouling coated hull.

The bonus of applying an epoxy barrier coating over all bare metal fittings is that there is less surface area of bare metal. Less surface area of bare metal equates to the need for less zinc (or other types of sacrificial anodes) needed to protect the boat’s underwater metal fittings and running gear from corrosion. Because of this, Zincs can last up to 2-3 times longer!

By addressing the high wear areas and applying an epoxy barrier coating on the metal my boat bottoms became the easiest to maintain in Marina Del Rey. The bottom paint jobs lasted longer and required less frequency of cleaning.

1980′s

Things have changed since the Environmental Protection Agency (EPA) outlawed the use of Tributyl Tin (TBT)in the 1980′s. Antifouling paint is not as toxic and does not remain as toxic as it did when it contained TBT. Because of this a third coat of antifouling paint on the high wear areas (instead of 4 coats) is sufficient to allow the paint job to sustain paint coverage equal to the longevity of the paint’s toxicity.

2014

Although the toxic characteristics of antifouling paint have been and are currently being assaulted by various organizations in regard to it’s environmental impact, the high wear areas of power and sailboats doesn’t change, and still needs to be addressed for the bottom paint job to sustain coverage. The need to use epoxy barrier coating still applies when using antifouling paint with cuprous oxide.

BOTTOM PAINTING RECOMMENDATIONS

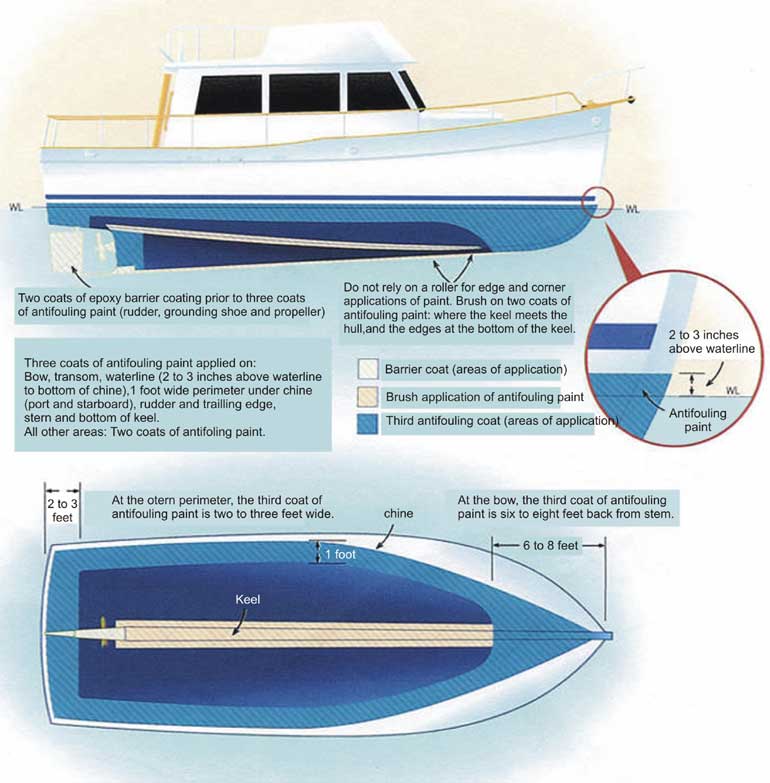

1. 2 Coats of epoxy barrier (example = Petit 4700/4701 ) over all metal fittings (except zincs ) below the waterline, such as propellers, struts, shafts, rudders, trim tabs , intake and discharge thru-hull fittings, etc. Note: Many boat yards discourage epoxy coating and painting the propellers and shafts, but we find that a 1/16″ to1/8″ thickness of coatings is better than 1″ to 2″ thick coral growth ( in Marina Del Rey, CA ). Note: ; Zinc usage is proportional to the amount of bare metal; No bare metal, no zinc usage. Epoxy coating eliminates bare metal.

2. 2 Coats of antifouling paint applied over entire bottom including previously epoxy barrier coated metal fittings.

3. One additional coat of antifouling paint applied over bow, waterline and rudders, transom and the tops of trim tabs on powerboats, and leading and trailing edge of keels on sailboats.

4. Always use a hard oil base antifouling paint, either red or blue in color ( Black is difficult to clean underwater, as you cannot see the growth from the paint) , with a high cuprous oxide content (60% or more). We prefer Proline 1088c or Petit Trinidad.

5. Outdrives: It is not always cost effective to paint the outdrives unless the outdrive paint contains tributyl tin (T. B. T. ) ; Outdrive paint without T. B. T. may only last 6-12 months, in which case it is more cost effective to clean the outdrives more often in lieu of new paint, although we have seen some good results with a paint called Sea Life.

Call these boat yards for estimates.

Marina Del Rey:

The Boat Yard: 310-823-8964,

Windward yacht Center: 310-823-4581

Sea Mark: 310-301-8303.

Channel Islands Harbor:

Anchors Way: 805-985-6775,

Bellport Marine Center: 805-985-1818.

Ventura Harbor:

Anchors Way: 805-642-6755.

Ventura Boat Yard: 805-654-1433

Tags: Boat Bottom Cleaning and Dive services in Marina Del Rey | Channel Islands Harbor | Oxnard | Ventura Harbor | Channel Islands Antifouling Bottom Paint | Channel Islands Propeller Replacement | Channel Islands Bottom Paint | Hull cleaning | Replace shafts | propeller replacement ventura harbor | trim tabs | replace zincs | diving services | Marina Del Rey Antifouling Bottom Paint | Marina Del Rey Propeller Replacement